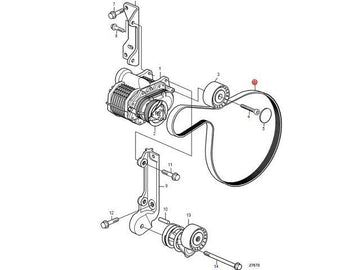

If you have a compressor version of the D4/D6 its important you know a bit about the compressor belt tensioner. It can be dangerous for the engine, as well as the maintainer. The compressor belt uses a spring loaded tensioner to maintain proper belt tightness. This can cause two issues.

The first issue is the tensioners are known to "grenade" over time. The device fails and since it's under spring tension it usually fails in a sudden and, for lack of a better term, explosive manner. This often sends the compressor belt into the serpentine belt, throwing it off one of its pulleys and causing both the coolant pump, and the sea water pump, to quit circulating vital cooling liquids. This can be quite dangerous in terms of warping parts of the engine, and causing damage to the vessel or its passengers if it strikes something from loss of propulsion/steering. The tensioner grenade usually results in a broken bolt that must be extracted before the new tensioner can be installed. Be careful not to "pull the pin" until you're 100% ready for tension or it becomes a fight to make adjustments. It's also quite an expensive part.

The second issue is the tensioners can make changing the belt quite dangerous. Volvo originally released a metal tool that fit inside the pulley of the tensioner and allowed a wrench or socket to be attached so the tensioner could be forced back against its tension to remove the belt. This tool often slipped or broke, often leading to injury of the user. Volvo subsequently released a new tool that is regarded as safer, but it requires the idler pulleys have been upgraded to the metal ones and this tool can still be quite dangerous to use. Changing the compressor belt can be a bit tedious and is a good service procedure to practice in the slip before trying to perform it at sea.

So how do we resolve these issues? Well, the first thing we like to remind our clients is the compressor is really only used in low-rpm and high-acceleration-demand situations before the turbocharger spools up. Most of the time boats can successfully accelerate gradually into turbo range without use of the compressor. It really only kicks in if you instantly demand a quick acceleration. Unless your engine really needs it, or you're doing water sports that require those rapid hole shots, we recommend just removing the compressor belt and tensioner all together. Keep the clutch plugged in and you won't get any alarms or codes on the engine. You may not have the acceleration you had with it, but if you can safely operate your boat without that low-end torque, then it will greatly diminish the risk of the two common issues associated with the compressor belt.

Whatever you decide to do, remember that safety is paramount. The safety of your vessel and passengers always takes precedent over the safety of the engines. At the very least be aware of the issues discussed in this article and be prepared to address either of them at sea.