Disclaimer: The use of Charge Air Cooler and Aftercooler are used interchangeably in this article and throughout most of the D6 literature.

The Charge Air Cooler (Aftercooler) is arguably the most important part of your Marine Diesel engine. We say that because if it fails, your engine will fail. This is especially expensive on a parent-bore engine like the D4/D6.

Your charge air cooler serves a very important role. As the intake air is compressed by the turbocharger it becomes quite hot and expanded. The colder and denser we can get that air the more fuel we can inject into the cylinder, and the more power we get out. One of the big advantages a marine engine has over diesel engines in other applications is we have an abundant source of cool-ish water at our disposal, regardless of whether the boat is moving or not.

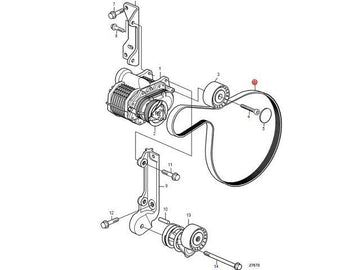

Trucks have giant secondary radiators for charge air coolers, often with electric fans to keep air flow and heat transfer going while the truck isn't moving. They take ambient air and blow it across metal fins attached to pipes that hot charge flows through and transfer heat into. But anyone who has ever jumped into a cold pool or lake knows we get quicker and better heat transfer from a fluid than we do from a gas. The D4/D6 Aftercooler takes the cool water from under the boat and pumps it through small metal tubes inside the cooler core. Those tubes are attached to fins to increase surface area for heat transfer. The hot air from the turbo blows across these fins/tubes and transfers heat into the water before going into the intake manifold and then the cylinders.

Even fresh water would be bad for an engine to ingest, but because lots of these engines operate in salt water it's even more important we keep the two sides of the charge air cooler separated. In the case of the D4/D6 charge air cooler this depends on the integrity of the insert (the tubes and fins) as well as four (4) o-rings which seal it to the housing and end caps.

The housing is constructed out of an aluminum. The insert is composed of various alloys. The end caps are either a bronze alloy or sometimes plastic depending on the model and year D4/D6. As discussed in other articles, dissimilar metals + salt water can be an equation for disaster if not closely monitored and properly maintained.

WHAT TO DO:

Years ago we adopted the Cummins Marine Aftercooler protocols from a well-reknowned Cummins Marine Guru, Tony Athens of Seaboard Marine, and applied them to Volvo aftercoolers. Many of Volvo's Aftercoolers are actually manufactured by the same company that Cummins uses on their marine diesel engines. Tony's articles and information can be found on his site www.sbmar.com as well as in this article:

Cummins Marine Aftercooler Maintenance.

We have even constructed our Cooler Service Kits to include everything Tony's kits do.

So what is the protocol? Every 2-3 years we remove the D4/D6 Aftercooler, completely disassemble and clean the parts, pressure test the inserts, inspect the housings, and reassemble the coolers with new o-rings and plenty of Alco MetalLube salt-water proof grease. The assembly is pressure tested again before installation. Frequent service ensures the coolers come apart easily and the layer of grease between the dissimilar metals stays in tact and protects the expensive housings which are prone to corrosion at the o-ring seats.

Stay tuned for videos of this process coming soon!

HOW TO CLEAN:

Brake cleaner is your friend. The local auto parts store usually has off-brand cleaner relatively cheap when bought by the case. Place the insert on absorbent pads or in a container to catch the oily-fluid that will come out. Blast it with brake cleaner until it comes clean. You can also use ultra-sonic cleaning to clean the insert but be very careful the solution and process does not damage the core. The aluminum fins can very easily be damaged and will begin flaking off into the intake of the engine. We have had good luck with Simple Green Extreme Aircraft and inexpensive ultrasonic machines from Vevor. A lot times it's cheaper and quicker for the customer to just blast it with brake cleaner and the end result is usually sufficient.

If the raw water side needs cleaning, bore punch the tubes using a rifle cleaning kit. We often flush the Aftercoolers with Rydlyme Marine before disassembly. Be careful using anything like Rydlyme or Barnacle buster on the charge air (fins) side of the insert.

HOW MUCH GREASE?

If you aren't sure, it's probably not enough. Use a brush to apply the grease anywhere dissimilar metals meet. We like to apply it to the o-ring seats and roughly 1" into the bore of the housing, to the housing face, end cap face, and the o-rings themselves. If it doesn't squeeze out while you tighten the bolts, it's probably not enough.

We want all the mating surfaces to have a layer of grease separating them and we want the o-rings to slide, not grab or pinch.

WHAT ABOUT RTV?

RTV is included in our kits solely for the mating surface of the Aftercooler "throat" (pipe) to the intake manifold. Volvo does not manufacture a gasket for this mating surface. Clean it up and lay a nice bead all the way around the mating surface and bolt holes. RTV is NOT to be used on any of the o-rings. A general rule of thumb is the only thing that should ever be applied to o-rings is grease.

PAINT IT!

We often get on boats where someone has serviced the coolers and its blatantly obvious because of the missing paint on the bolts and where the end caps have been separated. It's always a let down that they put so much effort and energy into overhauling a part of the engine and didn't finish the job with a fresh coat of paint. Before mounting the cooler, give it a good wipe down, some fresh primer, and paint. Even if it's just Gloss White. Paint not only makes it look pretty and finished, it protects everything from future corrosion.

REPAIRS AND REPLACEMENT PARTS:

If your housing has significant corrosion you will want to have it replaced. To date, this is only available through Volvo Penta. During supply chain issues we've had luck with a local machine shop using two-part epoxy Belzona to restore o-ring seats but out recommendation is to increase inspection/service frequency if you go that route.

Replacement inserts, end caps, hoses, clamps, o-rings, anodes, anode plugs, etc are all available through D6Parts.com and our friends at Swedish Lorry Parts. Now that quality aftermarket parts are available at significant savings there's just no excuse not to service your Aftercooler every 2-3 years.

If you're not comfortable doing it yourself, we can always help you pull the Aftercooler and send it to us for servicing! Teamwork is the Dreamwork!